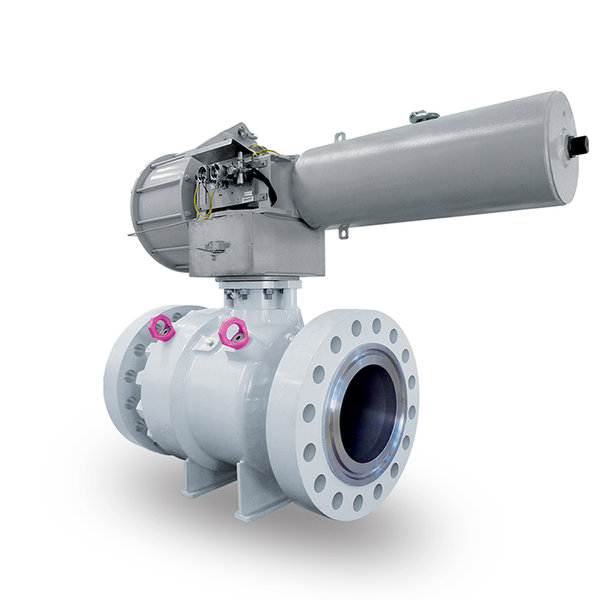

Side Entry Ball Valve

Highlights

- Compact envelope

- Reliable performance

- Suitable for above ground or below ground installation

ATV supplies a full range of Side Entry Ball Valves, trunnion mounted, two (cast) or three (forged) pieces, for onshore and offshore topside applications in the Oil & Gas exploration, production and transmission.

Side Entry Ball Valve offers the advantage of a compact envelope, reliable performance and a cost effective solution. Typically, soft-seated configuration is available for clean service whereas metal-to-metal sealing is the preferred choice for highest reliability in harsh service with the presence of solid particles, high pressure and high temperature.

ATV supplies Side Entry Ball Valves in a wide range of materials and configurations to meet any specific need of the application and customer’s requirements. Many optional features are available for seat designs, seat and stem sealing and end connections.

ATV ball valves are suitable for manual operation or for power assisted operation. ATV takes full responsibility in selecting the most suitable size for operating conditions. However, ATV welcomes customers supplied items too: in such a case ATV responsibility is limited to the assembling of the actuator on the valve and testing of valve and actuator system. On request, ATV may participate in the actuator selection together with the customer.

Materials are sourced from qualified suppliers on the base of specifications that reflect the industry standards (API, ASTM, NORSOK, BS, DIN or others), but do also incorporate additional requisitions resulting from long experience.

ATV designs, manufactures and tests its products in accordance with all the relevant Industry standards and codes (ANSI, API, ASME, BS, ISO, NACE, PED and others). ATV ball valves can be manufactured to conform up to product specification level PSL 3/3G.

ATV stresses its willingness to produce engineered valves; therefore, it welcomes requests for special size, class and design requirements.

Images

Side Entry Ball Valve - Specifications

SPECIFICATION

| MAIN DESIGN STANDARD | API 6A / ISO 10423 | API 6D / ISO 14313 |

| APPLICATIONS | Upstream applications, HIPPS System | Pipelines, rigs, platforms, HIPPS, skids, production plants |

| APPLICABLE STANDARDS | API 6A, ISO 10423, ASME VIII, ASME B16.34, ASME B16.10, ASME B16.5, NACE MR0175 and other diffused Industry standards | API 6D, ISO 14313, ASME VIII, ASME B16.34, ASME B16.10, ASME B16.5, NACE MR0175 and other diffused Industry standards |

| RANGES | 2 1/16” ÷ 7 1/16” Class 3000 psi and Class 5000 psi, 1 13/16” ÷ 9” Class 10000 and Class 15000 psi, 1 13/16” ÷ 7 1/16” Class 20000 psi. Any other size upon application. | 2” ÷ 60” Class ANSI 600, 2” ÷ 48” Class ANSI 900, 2” ÷ 36” Class ANSI 1500, 2” ÷ 20” Class ANSI 2500. Larger sizes available on request. |

MAIN FEATURES

| Forged body construction (3 pieces body) | ||

| Cast body construction (2 pieces body) | ||

| Bolted closure | ||

| Trunnion mounted | ||

| Full bore or reduced bore | ||

| Single piston effect (SPE) seats | ||

| Soft or Metal seated | ||

| Wear resisting hardfacing on sealing surfaces | ||

| Double Block and Bleed (DBB) | ||

| Anti-Blowout stem | ||

| Fire-Safe design | ||

| Qualification to PR2 |

END CONNECTIONS

| Flanges (to API 6A / ISO 10423) | ||

| Flanges (to ASME B16.5 up to 24” and B16.47A for 26” and larger) | ||

| Compact flanges (to Norsok L005) | ||

| Buttwelded ends (to ANSI 16.25) | ||

| Hub ends for clamped connections (as per customer requirement) |

MATERIALS

| Carbon steel with partial or full CRA overlay on the wetted areas | ||

| Low alloy carbon steel with partial or full CRA overlay on the wetted areas | ||

| Stainless steel | ||

| Duplex or Superduplex stainless steel | ||

| Nickel Alloy |

OPERATORS

| Handwheel or manual gear | ||

| Electric Multi-Turn | ||

| Pneumatic quarter turn actuator | ||

| Hydraulic quarter turn actuator |

OPTIONS

| Double piston effect (DPE) seats or mixed configuration (SPE/DPE) | ||

| Stem-Sealant injection | ||

| Seat-Sealant injection | ||

| Stem extension for underground installation | ||

| Extended yoke for high-temperature o low-temperature service | ||

| Cryogenic service design | ||

| Double Block and Bleed (DBB) |